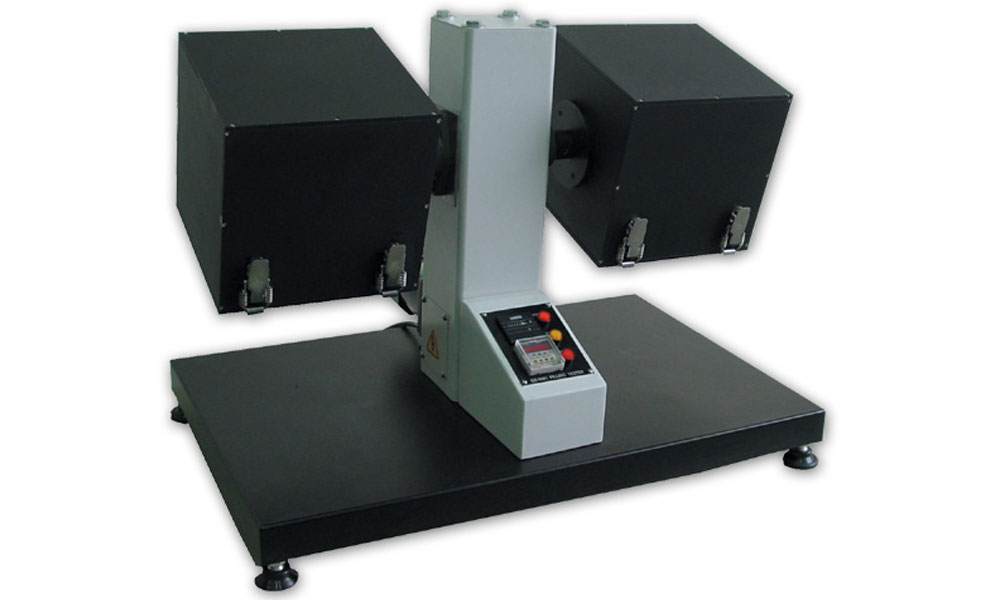

Test Application: To determine weight of a particular fabric.

Standards: ASTM D3776, ISO 3801, BS 2471, GB/T 4669

Cutter uses a drawing action to cut accurate circular samples with smooth edges. Even difficult materials such as fine knits, thin voiles, synthetic materials, heavy weight fabrics can be cut conveniently. The base is of porous rubber, which allows the cutters to cut into the base with complete safety. With PS100N, samples ranging from thickness 0.01mm to 5mm can be cut.